It is no surprise that countless semiconductor companies are integrating AI and ML into their operations with the hope of transforming dispatching, scheduling, equipment control and productivity, and robotic management. This ensures various technology, like IC chips, graphics processing unit (GPU), autonomous vehicles and intelligent robots, microprocessors, and more, are optimized effectively.

Overall, integrated circuit and data movement speed performance is enhanced when AI and ML is used, and in this article, you'll find out exactly why.

A forward-thinking & innovative concept

As more companies in the Semiconductor industry look to increase productivity in various areas, including field-programmable gate arrays (FPGAs), data storage and microcontrollers, AI/ML has become an important tool to accomplish this feat.

Before AI, optimization methods in the industry were a lot more manually operated and related software was in its beginning stages. The processing time for chip production required heavy testing, which meant analysis was performed by humans or by using early forms of AI/ML tools. Simple recognition and analysis was useful but with the advanced AI applications of today, companies can predict and track losses at every stage of the production process, significantly cutting losses and costs.

Thankfully, AI/ML has come a long way, and with it, advanced applications and software tools that successfully optimize operations across many different industries.

AI and ML currently contribute to about US$3-5 billion in earnings. In the next three years, that is predicted to rise to over US$30 billion. Within the semiconductor industry, the long-term financial gains are astronomical. AI/ML can generate over US$80 billion for semiconductors companies.

AI & ML use cases in semiconductors

For the entire value chain of semiconductor-device makers, AI/ML use has proven valuable in multiple specific cases. One example is the desire for reliable demand forecasting and inventory optimization. With AI/ML algorithms, semiconductor companies can analyze industry data and gain valuable insight to optimize manufacturing, procurement, and sales and operations planning.

There are substantial benefits to integrating AI/ML tools into the semiconductor industry. One of the most significant is how much it reduces manufacturing costs. According to McKinsey & Company, most companies see a 13-17% decrease in the cost of goods sold and product deprecation. There is also about a 10-14% decrease in administrative, sales, and general spending. The largest impact, however, has been seen mostly in R&D. When effectively implemented, companies in the semiconductor industry saw a 28-32% reduction in research and design costs.

It is essential to maintain a stable supply chain with an efficient logistics network, and part of that is because of its integration of AI and ML tools into company operations. Today, many great semiconductor companies are succeeding in developing semiconductor devices, IC chips, LED components, and much more.

(1) How AI & ML helps with semiconductor manufacturing

Simply put, AI/ML algorithms and tools help improve yields, increase a fab's throughput, and, most importantly, reduce manufacturing costs by up to 17%.

For example, using live tool-sensor data, metrology readings, and tool-sensor readings generated by machine learning tools, semiconductors can gain insight into etch dept, process time, and outcomes. Consequently, this potentially helps them reduce waste and damage to chips.

Visual inspections, especially of wafers, are also a major benefit of AI/ML tools in the industry. Deep learning via advanced computer systems has helped generate modern wafer inspection systems. This allows companies to detect wafer defects automatically, proving much more effective than human inspections.

(2) How AI & ML helps in research and chip design

As mentioned above, AI and ML tools help reduce research and design costs by up to 32%. This is clearly seen in the use of automatic yield learning to help with integrated circuit design. Semiconductor companies understand that mistakes made when designing IC chips or integrated circuits can lead to costly repairs and challenging iterations. Simply put, AI-based analytics help break IC designs down into essential components, which is beneficial for many reasons. With advanced ML algorithms, companies can identify significant patterns to predict potential failures, optimize layouts, and greatly improve yields.

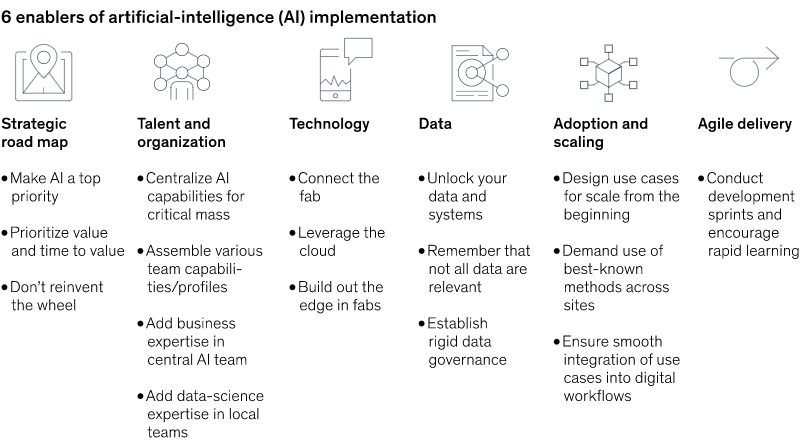

(3) 6 enablers needed for successful AI & ML integration

For any semiconductor company looking to transform its digital production and analytics, it is essential to follow a set practice. The six important tools needed are talent and organization, a strategic road map, data, technology, adoption and scaling, and agile delivery.

Talent and organization: Organize team capabilities, implement business, AI, and data-science expertise

Strategic road map: Prioritize AI, time, and value

Data: Establish effective data management and resources

Technology: Utilize cloud services and fab resources

Adoption and scaling: Integrate integrations smoothly for digital workflow, design use cases at the start, and utilize best-known practices.

Agile delivery: Ensure rapid learning and development sprints.

To sum up

AI and ML tools have been successfully integrated into the semiconductor industry, and many companies are enjoying the countless benefits these tools provide for their sensors, neuromorphic chips, and more. This includes improving yield, reducing waste and product damage, and optimizing development and operations.

To learn more about Heisener, a dedicated electronic component distributor since 2014, and how they can provide you with the integrated circuit chips, A dedicated electronic component distributor since 2014, and how they can provide you with the integrated circuit chips, semiconductor devices, electronic components and more you need to transform your business visit their site.

Stay connected on Facebook, LinkedIn and Twitter.